Digital Twin Technology

🏭 What is a Digital Twin? A Complete Guide for Business Leaders

Understanding the technology that's revolutionizing manufacturing, healthcare, and smart cities

Digital Twin Technology

Understanding the technology that's revolutionizing manufacturing, healthcare, and smart cities

A digital twin is a virtual replica of a physical

object, process, or system that's continuously updated with real-time data from sensors, IoT

devices, and other sources. It's not just a 3D model — it's a living, breathing digital

representation that mirrors its physical counterpart.

Key

Characteristics:

✅ Real-time data synchronization

✅ Bidirectional

data flow (physical ↔ digital)

✅ Predictive analytics and simulation

✅ Historical

data tracking and analysis

✅ What-if scenario testing

The Three Types of

Digital Twins:

🔧 Component Twins: Individual parts or

components (engine, pump, sensor)

🏗️ Asset Twins: Complete systems

(aircraft, building, production line)

🌐 Process Twins: Entire workflows

or operations (supply chain, manufacturing process)

Digital twins combine several technologies to create

an accurate, dynamic representation:

1. Data Collection

• IoT sensors

capture real-time data (temperature, pressure, vibration, etc.)

• Historical data provides

context and patterns

• Manual inputs and inspections add qualitative data

2.

3D Modeling & Visualization

• CAD models or 3D scans create the visual

representation

• GIS data for spatial context

• Real-time rendering for interactive

exploration

3. Data Integration & Processing

• Cloud platforms

aggregate data from multiple sources

• APIs connect to enterprise systems (ERP, MES,

SCADA)

• Data normalization and cleaning

4. Analytics & AI

•

Machine learning identifies patterns and anomalies

• Predictive models forecast future

states

• Optimization algorithms suggest improvements

5. Visualization &

Interaction

• Dashboards display key metrics

• 3D interfaces for immersive

exploration

• AR/VR for on-site visualization

• Alerts and notifications for critical

events

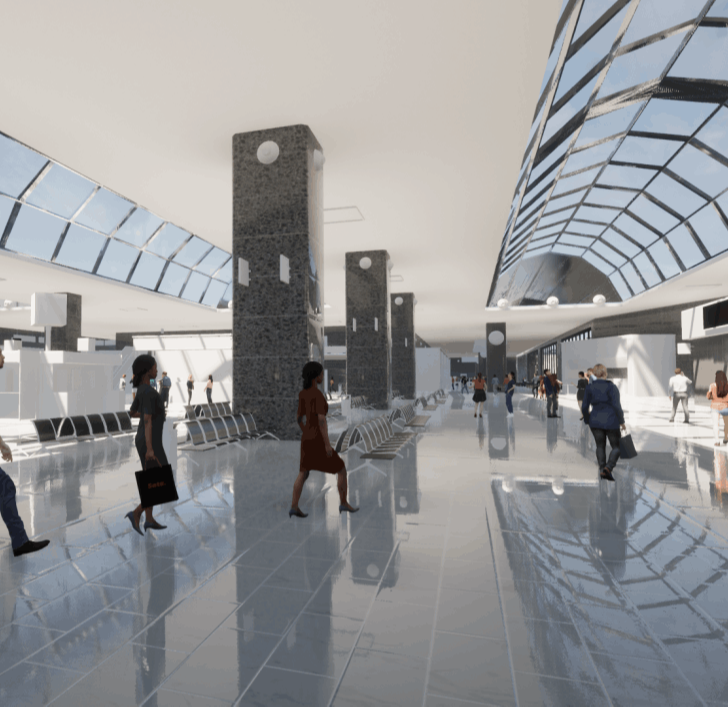

Real-time digital twin monitoring

Immersive 3D digital twin

🏭 Manufacturing

• Predictive

maintenance to prevent downtime

• Production optimization and bottleneck identification

•

Quality control and defect prediction

• Virtual commissioning of new lines

🏥

Healthcare

• Patient-specific digital twins for treatment planning

• Hospital

operations optimization

• Medical device performance monitoring

• Drug development and

testing

🏙️ Smart Cities

• Traffic flow optimization

• Energy grid

management

• Building performance monitoring

• Emergency response

planning

✈️ Aviation & Aerospace

• Aircraft health monitoring

•

Flight simulation and training

• Supply chain optimization

• Maintenance

scheduling

⚡ Energy & Utilities

• Power plant optimization

• Wind

farm performance

• Grid stability and load balancing

• Renewable energy

forecasting

🏗️ Construction & Real Estate

• Building lifecycle

management

• Energy efficiency optimization

• Space utilization analysis

• Preventive

maintenance

Companies implementing digital twins report

significant measurable benefits:

Cost Reduction

• 20-50% reduction in

maintenance costs

• 10-30% decrease in downtime

• 15-25% improvement in operational

efficiency

• Reduced need for physical prototypes

Performance

Improvement

• 30-40% faster time-to-market

• 15-20% increase in asset

lifespan

• 25-35% improvement in product quality

• Better resource

utilization

Risk Mitigation

• Predict failures before they occur

•

Test changes in virtual environment

• Reduce safety incidents

• Improve compliance and

auditing

Innovation Acceleration

• Rapid prototyping and testing

•

Data-driven decision making

• Continuous improvement cycles

• New business model

opportunities

General Electric (GE)

Created

digital twins of jet engines and wind turbines, reducing unplanned downtime by 20% and saving

millions in maintenance costs.

Siemens

Uses digital twins to optimize

manufacturing processes, reducing time-to-market by 30% and improving product quality by

25%.

Tesla

Every Tesla vehicle has a digital twin that's continuously

updated, enabling over-the-air updates and predictive

maintenance.

Singapore

Built Virtual Singapore, a digital twin of the

entire city-state used for urban planning, disaster response, and sustainability

initiatives.

NASA

Pioneered digital twin technology for spacecraft,

using virtual replicas to monitor and troubleshoot missions in real-time.

Ready to implement digital twin technology? Here's a

practical roadmap:

Step 1: Define Your Use Case

• Identify specific

business problem to solve

• Set measurable goals and KPIs

• Determine scope (component,

asset, or process)

Step 2: Assess Data Readiness

• Inventory existing

sensors and data sources

• Identify data gaps and requirements

• Plan IoT infrastructure

upgrades if needed

Step 3: Choose Technology Stack

• Cloud platform

(Azure, AWS, Google Cloud)

• IoT connectivity (MQTT, OPC UA)

• 3D visualization (Unity,

Unreal Engine, WebGL)

• Analytics and AI tools

Step 4: Build Proof of

Concept

• Start small with limited scope

• Validate data accuracy and

usefulness

• Demonstrate ROI to stakeholders

Step 5: Scale and

Integrate

• Expand to additional assets or processes

• Integrate with

enterprise systems

• Train teams on usage and interpretation

Step 6: Optimize

and Iterate

• Continuously refine models and algorithms

• Add new data

sources and capabilities

• Measure and report on business impact

🤝 How Simam Digital Can Help

Here's how we help you build your digital

twin:

🏗️ 3D GIS terrain generation and visualization

📊 Real-time data

integration from IoT sensors

🎯 Custom dashboards and analytics

🥽 AR/VR

interfaces for immersive exploration

🤖 AI-powered predictive maintenance

models

☁️ Cloud-based scalable architecture

🔄 Integration with existing

enterprise systems

📩 Ready to explore digital twin technology for your

business?

Let's discuss your use case and build a proof of concept together.

View our case studies for

more: 📋

Contact us today

or email us at: sales@simamdigital.com

Senior XR Engineer & Founder, Simam

Digital

https://www.linkedin.com/in/junaid-malik/